RPA in Manufacturing: Driving Efficiency and Innovation

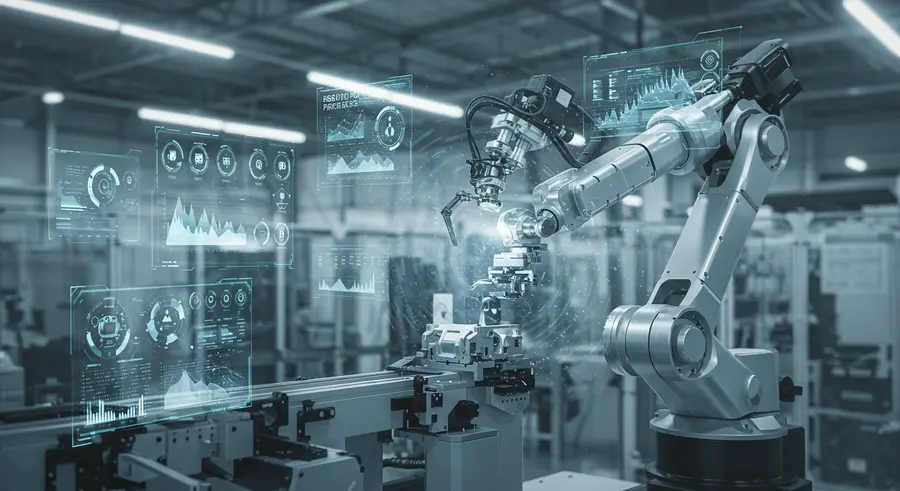

The manufacturing sector, traditionally known for its physical automation, is now undergoing a significant digital transformation powered by Robotic Process Automation (RPA). RPA introduces a layer of software-based automation that streamlines administrative and operational tasks, complementing existing industrial automation and paving the way for smarter, more efficient factories.

What is RPA in Manufacturing?

RPA in manufacturing involves deploying software robots (bots) to automate repetitive, rule-based processes that typically require human interaction with computer systems. These processes can range from data entry and report generation to managing supply chain logistics and quality checks. By automating these tasks, manufacturers can reduce errors, accelerate operations, and free up human employees to focus on more complex, strategic, and value-added activities.

Key Applications of RPA in Manufacturing:

- Supply Chain Management: Automating order processing, supplier onboarding, invoice reconciliation, and inventory tracking. RPA bots can monitor stock levels, trigger reorders, and update systems, ensuring a smooth and efficient supply chain.

- Production Planning and Scheduling: Streamlining the creation of production schedules, monitoring equipment performance, and automating data collection from various systems to inform production decisions.

- Quality Control and Assurance: Automating data validation from quality checks, generating reports, and even triggering alerts for discrepancies. RPA can ensure adherence to quality standards and regulatory compliance.

- Financial Operations: Automating accounts payable/receivable, expense management, and financial reporting. This helps in faster reconciliation and improved financial accuracy, especially when managing financial operations.

- Customer Service: Automating responses to common inquiries, processing returns, and managing customer data, thereby improving customer satisfaction and service efficiency.

- Human Resources: Automating onboarding processes, payroll management, and leave requests, allowing HR teams to focus on strategic talent management.

Benefits of Implementing RPA in Manufacturing:

- Increased Efficiency and Throughput: Bots work 24/7 without fatigue, significantly speeding up process execution and increasing overall operational capacity.

- Cost Reduction: By automating manual tasks, businesses can reduce operational costs associated with labor, errors, and rework.

- Improved Accuracy and Reduced Errors: RPA bots execute tasks with 100% accuracy, eliminating human errors and ensuring data integrity.

- Enhanced Compliance: Automated processes follow predefined rules strictly, ensuring adherence to regulatory requirements and internal policies.

- Faster Time-to-Market: Streamlined processes in design, production, and supply chain can accelerate product delivery.

- Better Data Analytics: RPA facilitates structured data collection, enabling deeper insights into manufacturing processes for informed decision-making.

- Scalability: RPA solutions can be easily scaled up or down to meet fluctuating demands without significant overhead.

Challenges and Considerations:

While the benefits are substantial, implementing RPA in manufacturing comes with its own set of challenges:

- Process Identification: Identifying the right processes for automation is crucial. Not all processes are suitable for RPA.

- Integration with Legacy Systems: Many manufacturing facilities rely on older, complex legacy systems which can pose integration challenges.

- Change Management: Employee resistance and the need for new skill sets require effective change management strategies.

- Security and Governance: Ensuring the security of automated processes and establishing robust governance frameworks are vital for long-term success.

The Future of RPA in Manufacturing:

The synergy of RPA with other advanced technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) is leading to "Intelligent Automation" in manufacturing. This hyperautomation trend will enable bots to handle more complex, cognitive tasks, such as predictive maintenance, smart quality inspection, and adaptive production scheduling.

As manufacturing moves towards Industry 4.0 and smart factories, RPA will play an increasingly pivotal role in creating fully integrated, autonomous, and highly efficient production environments. This will not only optimize current operations but also drive innovation and create new business models.

For further reading on industrial automation and smart technologies, you can explore resources from leading industry publications such as Manufacturing.net and Robotics Business Review.